Turpentine Uses And How To Make It - Survival Manual

How to Make Turpentine:

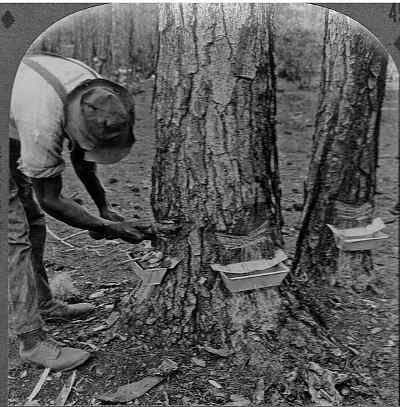

Turpentine is distilled from pine resin. Different species of pine, spruce and fir can be used as sources of pine sap. Traditionally longleaf pine and slash pine were used when pine sap was collected commercially for turpentine production in years past.

This resin is collected from pine trees by either cutting the pine tree or simply collecting the sap that you can find on pine trees that have already been damaged. This can be from where insects have eaten into the tree or where a limb has broken off or where the tree is damaged by a canker.

To make turpentine will need a simple distillation system. This can be nothing more than a small can with a top. Connect a pipe or metal tubing to the can. A perfect seal is not necessary, but of course it will be more efficient if it is properly sealed. As you heat the pine sap you will melt the sap and vapors will begin to outgas from the sap. These vapors will travel down the pipe and must be cooled before escaping the pipe.

Cooling the vapors condenses them into a liquid. This liquid is the turpentine that you seek. The turpentine is simply collected in a jar at the end of the pipe or tubing. Running water over the pipe or tubing will cool it down and condense the vapors into a liquid. Cool the pipe as you heat the sap. The vapors will condense in the pipe which you can collect as a liquid in a jar.

Rosin is what is left behind in the distilling pot.